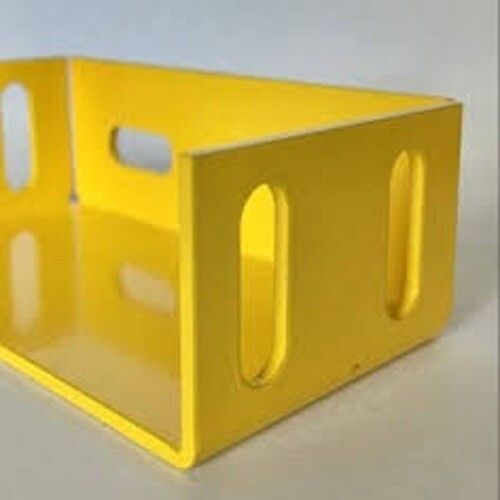

Sheet Metal Powder Coating

Product Details:

Sheet Metal Powder Coating Price And Quantity

- 100 Square Foot

- 20.00 - 25.00 INR/Square Foot

- 20 INR/Square Foot

Product Description

Sheet metal powder coating is a finishing process used to apply a protective and decorative layer of paint to sheet metal surfaces. It involves applying a dry powder paint material to the metal substrate, then curing it to form a durable and uniform coating. Here's an overview of the process:

-

Surface Preparation: Before powder coating, the sheet metal surface must be properly cleaned and prepared to ensure adhesion and uniform coverage of the coating. This typically involves cleaning the metal surface to remove dirt, oil, grease, rust, and other contaminants. Surface preparation methods may include degreasing, chemical treatment, sandblasting, or mechanical abrasion.

-

Powder Application: Once the surface is prepared, the powder coating material is applied to the sheet metal using an electrostatic spray gun or a fluidized bed system. The powder particles are charged electrostatically, causing them to adhere to the grounded metal substrate. This results in a uniform and even coating thickness.

-

Curing: After the powder is applied, the coated sheet metal is transferred to a curing oven, where it is heated to a specified temperature. The heat causes the powder particles to melt and fuse together, forming a smooth and durable coating. The curing process typically takes place at temperatures ranging from 300 to 450 degrees Fahrenheit (150 to 230 degrees Celsius) for a duration of 10 to 30 minutes, depending on the specific powder coating material used.

-

Cooling and Inspection: Once the curing process is complete, the coated sheet metal is allowed to cool to room temperature. After cooling, the coated surface is inspected for defects such as bubbles, runs, or uneven coverage. Any defects can be rectified through additional coating or refinishing as needed.

-

Post-Curing and Testing (Optional): In some cases, a post-curing process may be performed to further enhance the coating's properties, such as its hardness, adhesion, or chemical resistance. Additionally, quality control testing may be conducted to ensure that the finished coating meets specified requirements for thickness, adhesion, appearance, and durability.

-

Finishing Touches: After powder coating, the sheet metal parts may undergo additional finishing processes such as masking, taping, or stenciling to achieve desired aesthetic or functional features

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sheet metal Fabrication' category

Other Address

G-15, Payal Complex, Manubhai Tower, Vadodara - 390010, Gujarat, India

|

LABTECH SYSTEMS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |