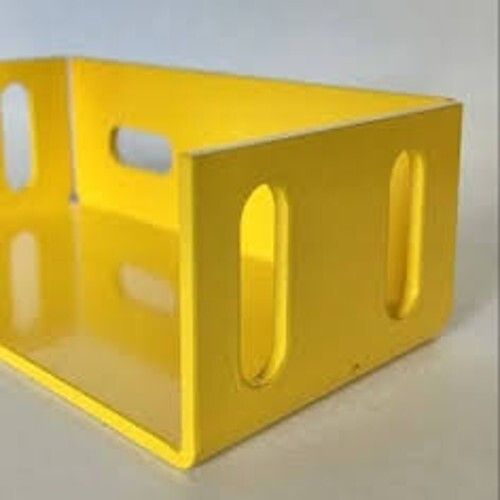

Panel Board Fabrication

Product Details:

- Size Standard

- General Use Indoor Furniture

- Assembly No Assembly Required

- Material ms

- Feature Easy To Clean

- Finish Powder Coated

- Click to View more

Panel Board Fabrication Price And Quantity

- 20000 INR/Unit

- 1 Unit

Panel Board Fabrication Product Specifications

- Standard

- Indoor Furniture

- Easy To Clean

- No Assembly Required

- Powder Coated

- ms

Product Description

Panel board fabrication involves the manufacturing of panel boards, which are used to house electrical components such as circuit breakers, switches, and meters. These boards are essential components of electrical distribution systems in residential, commercial, and industrial buildings. Here's an overview of the process:

-

Design: Panel board fabrication typically starts with the design phase, where engineers or designers create detailed schematics and layouts based on project requirements, electrical codes, and safety standards. The design specifies the size, configuration, and arrangement of components within the panel board enclosure.

-

Material Selection: Panel boards are commonly made from sheet metal, such as steel or aluminum, although other materials like plastic or fiberglass may also be used depending on the application. The choice of material depends on factors such as durability, electrical insulation properties, and environmental considerations.

-

Fabrication: The fabrication process involves several steps, including:

- Cutting: Sheet metal may be cut to size using shearing machines, laser cutters, or other cutting tools.

- Bending: The cut metal sheets are then formed into the desired shapes and angles using press brakes or other bending equipment.

- Punching: Holes and cutouts for mounting components and cable entry points are punched or drilled into the metal panels.

- Welding: In some cases, metal panels may be welded together to form the enclosure structure.

- Assembly: Electrical components such as circuit breakers, bus bars, terminal blocks, and wiring are installed and connected according to the design specifications.

-

Finishing: After fabrication and assembly, panel boards may undergo finishing processes such as painting, powder coating, or plating to improve aesthetics and provide corrosion resistance.

-

Testing and Quality Control: Before being put into service, panel boards undergo rigorous testing to ensure proper electrical functionality, safety, and compliance with relevant standards and regulations. Quality control measures are implemented throughout the fabrication process to detect and correct any defects or deviations from the design specifications.

-

Installation: Once fabricated and tested, panel boards are installed in their designated locations within electrical systems, typically mounted on walls or within equipment enclosures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sheet metal Fabrication' category

Other Address

G-15, Payal Complex, Manubhai Tower, Vadodara - 390010, Gujarat, India

|

LABTECH SYSTEMS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |